Application: Chemical Pump

Problem

Water-powered pump is used to dispense fertilizers, disinfectants, chlorine, acids, soaps, pharmaceuticals & nutritional supplements in a wide range of settings. Internal components are exposed to a number of chemicals, and must resist corrosion & wear against stainless steel components within the pump.

Solution

RTP 100 Series polypropylene with PFPE.

Benefits

- Excellent wear resistance

- Eliminates need for separate metal or plastic bearings

- Improved coefficient of friction in moving components

- Excellent chemical and corrosion resistance

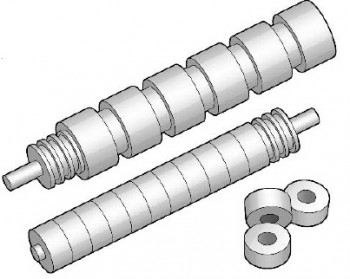

Application: Conveyor Rollers

Problem

Food conveyor rollers used in food processing equipment need to withstand constant movement & must be easy to clean to reduce risk of contamination. Material used in the rollers needs to be approved for food contact & have excellent wear resistance.

Solution

RTP 800 Series acetal with PTFE & silicone.

Benefits

- Improved wear resistance

- Excellent lubricity

- FDA compliant

- Chemical resistance to cleaning solutions

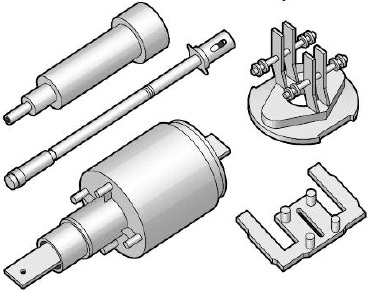

Application: Disposable Pump

Problem

Traditional metal pumps used in the food, dairy, chemical, medical and pharmaceutical industries face contamination issues, which create down-time for maintenance and high cleaning costs. Multiple material requirements include: wear resistance, maintaining low warpage and low creep at operating temperatures of 110°C (230°F), and low moisture absorption to minimize swelling.

Solution

RTP 1300 Series polyphenylene sulfide glass fiber reinforced compound with PTFE.

Benefits

- Excellent chemical resistance

- No need for external lubricants

- FDA compliant polymers and ingredients

Application: HVAC Gears

Problem

Due to extreme temperature changes (-40 0c to 80 0c) gears were creating excessive noise leading to warranty issues.

Solution

RTP 200 series and 800 series with glass fiber and PTFE.

Benefits

- Noise reduction

- Low friction

- Improved wear resistance

Application: Micro Pump Gears

Problem

Chemically resistant materials need to pump a wide variety of fluids over a wide temperature range including: espresso, water, pesticides, carbonated drinks, & alcohol. Application requires high wear materials but cannot utilize glass fiber.

Solution

RTP 2200 Series Peek with carbon fiber, aramid fiber & PTFE.

Benefits

- Excellent chemical & corrosion resistance

- High strength

- Wear resistant

- High heat resistance – Many micro pumps operate at very high speeds creating high temperatures at the wear interface

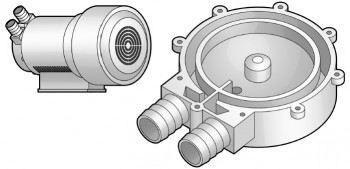

Application: Positive Displacement Transfer Pump

Problem

Pump must be light weight and capable of moving hydrocarbons & other chemicals in mining, agriculture, marine, chemical, petroleum, & transportation industries in a range of environmental conditions.

Solution

Impeller: RTP 1300 Series compound with carbon fiber, PTFE & PFPE

Impeller Housing: RTP 2200 Series compound with carbon fiber, PTFE & PFPE

Wiper Blade: RTP 2200 Series compound with PTFE

Benefits

- High strength

- Excellent chemical resistance

- Superior abrasion & wear resistance

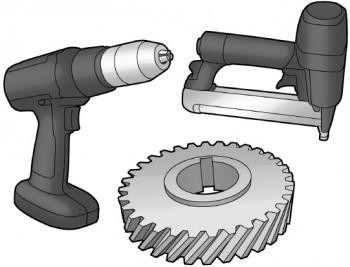

Application: Helical Gears for Power Tools

Problem

Power tools need a lightweight moldable plastic that meets high strength and wear resistance requirements. Eliminate the need for expensive machined steel gears.

Solution

RTP 4000 Series PPA with carbon fiber and silicone.

Benefits

- Very high strength

- Moldable to net shape

- Wear resistance

- Quiet operation

- Suitable for high speeds

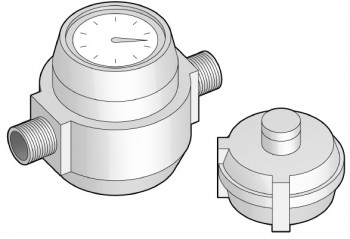

Application: Water Meter

Problem

Water meter design incorporates a nutating disc, which must poses good wear properties and tight tolerances with long term water exposure.

Solution

RTP 400 and 500 series with graphite, PTFE, silicone and or glass.

Benefits

- Tight molding tolerances

- Dimensional stability

- Hydrolytic stability

- Excellent wear properties and low coefficient of friction

- NSF approval for water contact

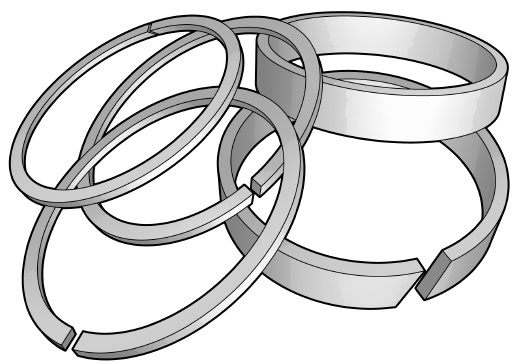

Application: Wear Rings

Problem

Wear rings are used in hydraulic cylinders and pistons. They require a material with good wear resistance and low coefficient of friction, and must maintain tight tolerances and perform against petroleum oils, fluids and greases over a temperature range of -40°F to +275°F.

Solution

RTP 207A Series TFE13 Si2 HS black heat stabilized glass reinforced nylon 6 with PTFE and silicone.

Benefits

- Resistant to petroleum oils, fluids and greases

- Dimensionally stable

- Combination of good wear resistance and low coefficient of friction

- Performs over a broad temperature range