RTP Company

Engineered Thermoplastic Compounds

Providing you with solutions, customization, and services for all your thermoplastic needs.

regular mold cleaning

Select a Custom Engineered Plastic Compound

We pair imagination with engineering to successfully imagineer a specialty compound with one or more of the following characteristics:

Our custom engineered thermoplastics are available in several formats for your application.

Pellets

From made-to-order high tech custom compounds to off-the-shelf unfilled resins, we provide thermoplastic pellets designed to meet your application requirements.

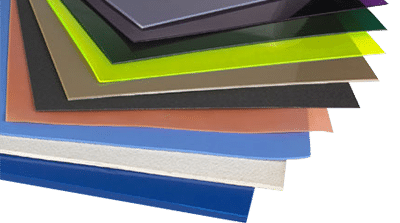

Sheet

Engineered Sheet ProductsTM (ESPTM), our sheet division, manufactures custom thermoplastic sheet in a range of widths, lengths and thicknesses.