Our Structural Compounds provide solutions in applications requiring excellent mechanical and/or thermal performance.

Short Glass Fiber (SGF) Compounds – chopped glass fiber provides strength and stiffness to our SGF compounds, which provide good, general purpose reinforcement.

Very Long Fiber (VLF) Compounds – in addition to the improvement in strength and stiffness versus SGF Compounds, VLF Compounds provide improved impact strength and are commonly used for metal replacement.

Carbon Fiber (CF) Compounds – our CF Compounds provide tremendous stiffness without adding significant weight to a vehicle. These high end materials, which are commonly used in aerospace, are finding broader use for lightweighting in electric and autonomous vehicles.

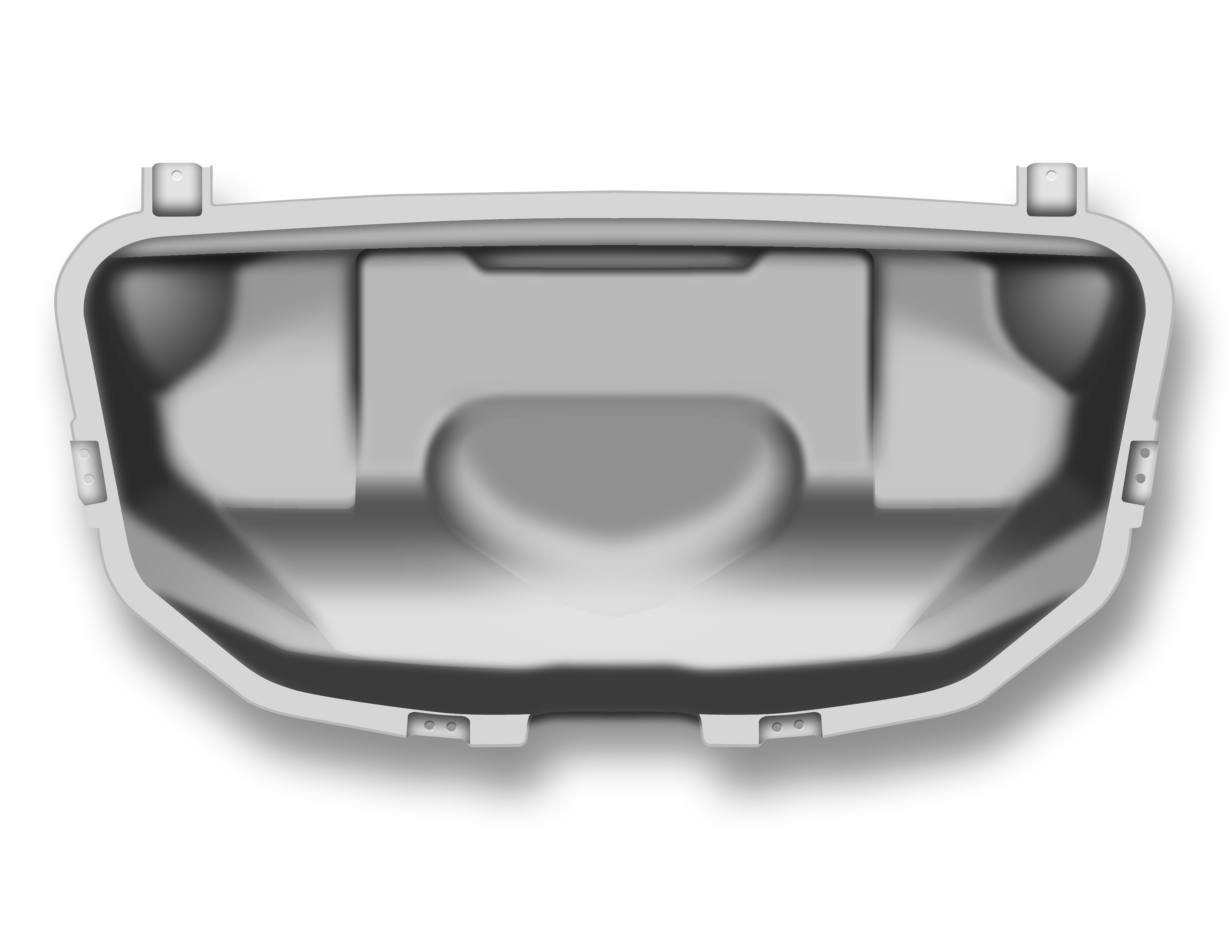

The “frunk”, or storage space under the front hood of an electric or autonomous vehicle, can be made from VLF Compounds for excellent durability and impact.

Description

Long Glass/Short Glass Fiber PP, PA, PBT; Carbon Fiber (CF) Compounds; ASA Alloys

Key Characteristics

Provide outstanding impact resistance, creep resistance, and aesthetic value

Benefits

Typical Applications

| RTP Company Material Options | |||||||

|---|---|---|---|---|---|---|---|

| RTP 299 A X 143325 A | RTP 299 A X 149343 A | RTP 199 X 154150 B | RTP 199 X 70815 |

RTP 199 X 70836 A | |||

| Property | Method | Unit | PA6 30% SGF | PA6 30% SGF Low Density | PP 20% CF | PP 30% VLF | PP 40% VLF |

| Density | ISO 1183 | g/cm3 | 1.35 | 1.22 | 1.00 | 1.13 | 1.20 |

| Tensile Strength | ISO 527 | MPa | 180 (113) | 167 (115) | 105 | 110 | 130 |

| Flexural Modulus | ISO 178 | MPa | 9500 | — | 9233 | 6500 | 8500 |

| Charpy Impact, Notched | ISO 179/1eA | kJ/m2 | 13 (15) | 10 (12) | 4.0 | 21 | 25 |

*All values Dry As Molded except those in parentheses, conditioned 23 °C, 50% RH to equilibrium.

For applications that require aesthetics, UV protection, and weatherability, we formulate ASA Alloys that provide high gloss, colorability, and UV performance. In addition, these alloys provide higher chemical resistance and thermal stability versus standard ABS, making them an excellent choice for thermoplastic housings on charging stations.

UV Resististance

| Property | ABS | PC/ABS | PP | PA | ASA |

|---|---|---|---|---|---|

| UV Resistance | POOR | POOR | BETTER | BETTER | BEST |