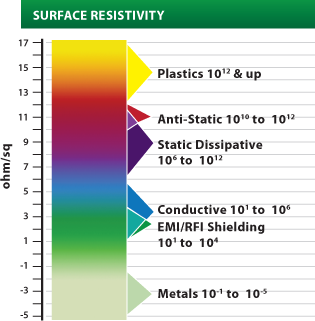

How can you effectively mitigate conductivity issues before they affect safety, productivity, and profitability? Our Conductive and Anti-Static Compounds offer electrical properties spanning the surface resistivity spectrum from 100 to 1012 ohm/sq and are formulated for injection molding or extrusion processing.

In all-polymeric grades, our conductive IDP polymers known as PermaStat® and PermaStat Plus® are alloyed with host resins; for others, conductive particulate or fibers are combined with a base polymer to form a conductive matrix. Available in natural, black, or colored particulate and all polymeric-based materials, we can tailor your compound to provide static dissipation, electrostatic discharge (ESD) protection, EMI/RFI shielding, or thermal management.

For more information about specific Conductive and Anti-Static Compounds, select from the menu below:

We continue to develop compounds that solve specific challenges in products affected by static buildup. In addition, we have expanded our hybrid technologies to include Electrostatic Paintable (EPP) Compounds, Conductive Compounds for Extrusion Applications, Conductive Thermoplastic sheets, Carbon-based compounds, and Highly Conductive Compounds. The fastest way to learn more is to contact your local sales engineer!