RTP Company offers a complete portfolio of thermoplastic materials for the automotive industry. We’ve successfully helped automotive manufacturers reduce vehicle weight, lower vehicle emissions, and increase safety for combustion engine and electric vehicles.

Electric & Autonomous Vehicle Resources

Brochure | Applications | Technologies

RTP Company’s light-weighting portfolio includes:

To learn more, see our Enlightened Solutions page.

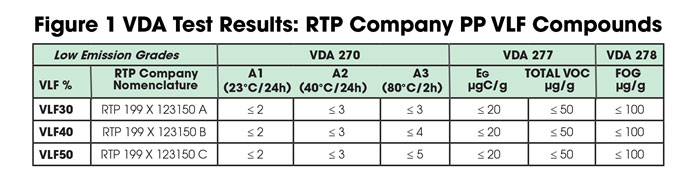

These environmentally-friendly VLF compounds can be used in automotive interior applications such as instrument panels, door module carriers, overhead and center consoles, seating, load floors, pedal boxes, spare tire covers and storage bins.

In addition to our low emission offering we are capable of making appearance friendly VLF PP materials to meet automotive interior and exterior requirements… UV stability, scratch and mar performance, low gloss, uniform surface appearance combined with the outstanding strength and impact of VLF.

RTP Company provides ready-to-mold plastic compounds with EMI Shielding properties that are ideal for the housings of automotive sensing systems. In addition to protecting sensing systems from the damaging effects of EMI, housings made from these compounds are significantly lighter than their metal counterparts, thereby reducing overall vehicle weight.

Learn more about EMI Shielding and Automotive EMI Sensing Systems by viewing our interactive page.

- High temperature Ultra Wear compounds for transmission seal rings and thrust washers

- EMI RFI shielding for electronic enclosures

- Electrically conductive compounds for fuel systems

- Thermally conductive compounds for LEDs and other heat sink applications

- Light Controlling Compounds for LED Electronics