Search Case Studies

End-Use Case Study

The popularity of lower profile cleats has stepped-up as a practical and functional alternative.

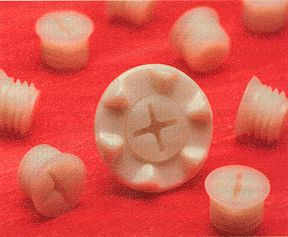

Moore, along with business partner Leonard Nosewicz, designed and began production of a ceramic cleat system which uses a high-impact nylon 6 (RTP 200 A Series) specialty compound for mounting screws. The ceramic cleats are nearly indestructible, and the screws play a critical role in the design of the application.

The mounting screw is made from an RTP 200A Series (high-impact nylon 6) compound with glass reinforcement. The specialty compound exhibits an un-notched impact strength of 17 ft. lbs./in. at 1/8 in. and a tensile strength of 13,500 psi. The screws are molded under strict quality standards by Cal-Tron Corp. of Bishop, CA.

Cal-Tron Corp. (619-873-8491) is a close-tolerance injection molder of engineered thermoplastics serving the communications, aerospace, sports, electronics and music industries. Gripper Golf Cleats, located in Golden, CO, is a division of Coors Ceramics based in Golden, CO.