Search Case Studies

End-Use Case Study

- Very Long Fiber Composite Reduces Weight While Retaining Durability For Robotics Gearbox

“Not everyone had a nearby robotics hobby store where they could find or fabricate the parts they envision. Those that didn’t were at a real disadvantage,” Baker said.

Seeing an opportunity to help the program, Baker and Mark Koors, also a FIRST mentor, started AndyMark, Inc. to provide a one-stop shop for specialized robotic parts as well as everything else needed by robot builders. The growing company now supplies the FIRST competitions as well as similar “bot” competitions along with hobbyists around the world.

As a company built on innovation, AndyMark’s founders frequently examine their catalog of components for ones that can be improved. Recently, an aluminum gearbox kit captured their attention. Baker, a trained mechanical engineer, believed the housing could be made with reinforced plastic, meaning fewer parts for easier student assembly, as well as reduced weight, and increased durability.

“Weight is a holy grail in these competitions,” noted Baker. “Everyone tries to get as much stuff on their robot as possible under the weight limit.”

Knowing of RTP Company’s reputation through previous work, Baker put the company’s engineers to work on a solution. The result was a material oriented redesign from which emerged a new gearbox with fewer parts, surer assembly, superior durability and, best of all, half a pound (1/4 kg) lighter in weight.

Further, the new kit costs about the same as the old one, no small concern for AndyMark. “These kids often run bake sales to earn the funds they need; we want to keep our prices at the lowest levels possible,” said Baker.

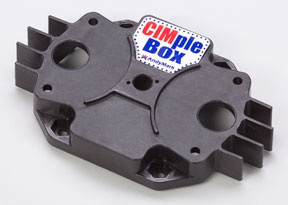

The material used is a RTP 200 Series very long fiber reinforced nylon 6/6 composite. It was used first in AndyMark’s Toughbox Mini gearbox, and then in their CIMpleBox gearbox, which this season become the standard gearbox for all FIRST robot kits — more than 2,000 teams used it without a single failure.

“We talked to a lot of builders and heard nothing but positive feedback about the new designs,” said Baker.

Partnering with a full-service custom compounder was instrumental to the success of the redesigned gearboxes. “RTP Company provided us with tremendous technical support, their CAE engineers did a flow analysis and ran deformation studies of different materials under load to help us identify the best solution,” said Baker. “We are now working with them on redesigning a third part, and look forward to working together more in the future.”

Founded in 2004, AndyMark, Inc. of Kokomo, IN, invents and designs components for robotics and mobility applications. For more information visit their website at www.andymark.com. To learn about FIRST go to www.usfirst.org.