Search Case Studies

End-Use Case Study

- Flame Retardant Compound Meets Multiple Design Criteria

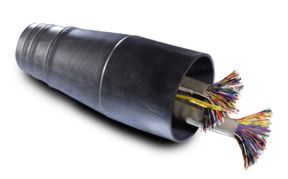

To direct and protect cables, Marconi manufactures a megaphone-shaped communications cone. Mounted in outdoor cabinets, the cone functions much like a traditional wiring harness, funneling cables and protecting them through climate changes as varied as the Earth’s terrain.

Originally molded from PVC, the cone was exposed to some extreme conditions that promoted the growth of fungus on the part. Additionally, new customer requirements demanded that the part meet more stringent specifications. Adherence to Bell specification BEL-GR-487-CORE for UV resistance and a UL flammability rating of V-1 at 0.088 inch (2.24 mm) had to be achieved with a single material. With the potential to be located just about anywhere, the part had to resist chemical attack from a wide range of sources. Further, the part needed both strength and flexibility through extreme temperature variations. Marconi, in conjunction with their molder, Parkway Products of Seneca, SC, searched for a new material capable of meeting the heightened performance demands.

RTP Company developed an RTP 2000 Series olefinic custom alloy compound with compatible UV stabilizer and flame retardant packages. Traditional flame retardant packages are known to interact with traditional UV stabilizers, depleting their effectiveness over time. Understanding these shortcomings, RTP Company engineers developed an innovative flame retardant and UV stabilizer combination. This package allowed the compound to exceed the flammability requirements and meet a V-0 rating.

The RTP 2000 Series alloy also met structural requirements of the 1/8 inch (3.2 mm) walled part. Tensile elongation of over 300% and a no break Izod impact performance provide both strength and flexible ruggedness without becoming brittle at low temperatures. Inherent anti-microbial properties of the material passed Marconi testing for inhibiting fungal growth.

Calvin Carter of Parkway Products credits RTP Company Technical Service personnel with a smooth material changeover. Initial processing temperatures proved too high, but this problem was readily corrected with a visit from RTP Company Technical Service staff. “We’ve really had no problems since the processing was initially optimized,” says Carter, “but they continue to check in with us to make sure things are going well.” And, as the previous material was a simple mechanical mix of different pellets, Carter appreciates the “real production gains that comes from having all the material requirements met with a single, uniform pellet.”

Marconi Communications of London, England is a global leader in telecommunications systems. For more information please visit their website at www.marconi.com. Parkway Products is a prominent custom molder located in Seneca, SC. For more information please visit their website at www.parkwayproducts.com. They may be contacted at (864) 882-5652.