Search Case Studies

End-Use Case Study

- PEEK™ Specialty Compound Stands Up To High Pressure Refrigerants

Visteon’s search for a molder that specializes in high-temperature, high-performance materials led them to QMR Plastics in River Falls, Wisconsin.

The opportunity for QMR came suddenly, with very short lead times. “We needed to jump on this and had to find a specialty compounder who could respond quickly,” said Darwin Nogelmeier, QMR’s Director of Sales. “We didn’t tell the suppliers it was a race, but wanted to see how quickly they could perform under normal circumstances. We contacted RTP Company the Friday before Labor Day weekend for a sample. It was delivered early Tuesday morning and was tested and approved before the others had a chance to react.”

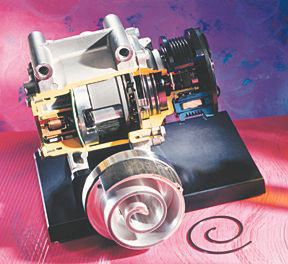

Scroll compressors work by squeezing the refrigerant into a progressively smaller chamber. The tip seals are located on the tips of the fixed and orbiting scrolls, functioning much like a piston ring. The seal is pushed up by high-pressure refrigerant and actually rubs over two holes. Without sufficient wear resistance and stiffness, the seal would be eaten away and eventually wear out.

RTP Company engineers worked rapidly to develop an RTP 2200 Series PEEK™-based compound that offered the right combination of wear resistance, stiffness, and high temperature performance. Tensile strength of the compound is 20,000 psi (138 MPa), and flexural strength is 32,000 psi (220 MPa). The material features heat deflection temperatures of 530 degrees F (264 psi) or 277 degrees C (1820 kPa).

QMR Plastics and PEEK™ compounds make natural partners. “We use hot manifold and hot runner technologies that give us an edge with high temperature engineering compounds. These processes shorten our cycle times and minimize regrind generation,” said Nogelmeier. “They’ve contributed to our tremendous growth in the last few years.”

Visteon Automotive Systems, an enterprise of Ford Motor Company, is headquartered in Dearborn, Michigan, and has 120 plants and engineering facilities worldwide. Visit their website at www.visteon.com.

QMR Plastics, a division of Quadion Corporation, has doubled its sales volume since 1995 and received national recognition for leading edge technology. Its new, state-of-the-art facility is in River Falls, Wisconsin. Call (715) 426-4700.

Victrex USA Inc., a division of Victrex plc., is the sole manufacturer and supplier of PEEK™ polymer worldwide. For more information, call (800) VICTREX.