Search Case Studies

End-Use Case Study

- Glass fiber reinforced PES available in five colors

- Lighter and better aesthetics than traditional stainless steel bases

- Chemical resistance to cleaning agents

RTP Company produced an RTP 1400 Series polyethersulfone compound that could withstand extreme temperature, chemical, and handling conditions. “These bases are expected to last at least three years,” explains Burk Wyatt, Manager of R & D at Aladdin Temprite. “They are heated three times a day in a convection cabinet at 235 degrees F (113 degrees C) for up to 2 hours. When you do the math, it totals over 6,000 hours of heat exposure. In addition to heat, the bases are exposed to dishwasher detergents and rinsing agents in commercial dishwashers three times a day. They must also stand up to rough handling and stacking.”

The glass fiber reinforced compound had to meet critical color matches so it partners well with other food service items such as cups, lids and dome covers. The material displays unnotched IZOD impact strength at 1/8 in of 11 ft lbs/in (587 J/m at 3.175 mm) and heat deflection temperature of 410 degrees F at 264 psi (210 degrees C at 1.82 MPa). A foodservice environment requires the compound to have FDA and NSF approvals.

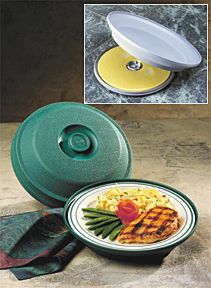

The base is constructed of an injection-molded top and bottom shell that contains a blow-molded, wax-filled bladder. The wax melts during the pre-heating process; as it solidifies, heat is given back to keep the food warm.

Bill Durden, Vice President and General Manager of molder Durden Enterprises, describes the manufacturing process. “This material is processed at temperatures exceeding 700 degrees F (371 degrees C). Once the shell is at room temperature, we sonic weld the perimeter as well as the center to prevent bulging during the heating process. The cycle time for each piece is about 50 seconds because of the large circumference of this part.”

In contrast to traditional stainless steel bases, the thermoplastic Insul-Plus™ offers long-lasting performance at a lower cost. Their light weight makes them easier to handle and reduces the total load being pushed on delivery carts. The bases come in five fashionable colors that improve aesthetics and avoid the institutional look of stainless steel.

Aladdin Temprite is located in Nashville, Tennessee. Contact them at (615) 748-3600 or visit their website at www.aladdintemprite.com. Molder Durden Enterprises in Auburn, Georgia, can be reached by calling (770) 963-0637 or www.durdene.com.