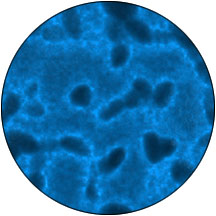

Untreated plastic articles can be attacked by microbic growth causing unsightly discoloration, unpleasant odors, and polymer degradation issues.

Antimicrobial additives can be incorporated with plastic resins during compounding or as a masterbatch during molding and provide a biocide treatment to control microbes.

Common microbes antimicrobials can be effective against include

Multiple antimicrobial technologies are available which are compatible with wide variety thermoplastic resins

Silver-based antimicrobials

Silver has been used for centuries as a biosatic agent. When contacted by moisture an electrochemical reaction releases silver ions. These ions penetrate microbes rendering them unable to function, grow, or reproduce.

A wide variety of plastic articles are suitable* for antimicrobial treatment

- Medical devices, FDA 510(k)

- Sports and recreation equipment

- Food processing and handling machinery

- Business machines and consumer appliances

- General household goods

- Textile films & fibers

- Transportation interiors

- Construction supplies

- Any outdoor applications

* In the United States usage and benefit claims are regulated by the EPA or guided by the FDA depending on usage.

Antimicrobial selection

- What is the end-use application and its typical usage environment?

- Do other products of this type already utilize antimicrobial protection?

- Is there a preferred technology for antimicrobial treatment?

- Does the antimicrobial additive need to function in a particular resin?

- Will other additives also be included in the resin?

- What antimicrobial efficacy or other performance requirements need to be met?

- What roll does cost have on antimicrobial technology selection?

Learn more about Antimicrobial Solutions

- INNOVATION BULLETIN: Antimicrobial Compounds

- DATA SHEETS: Antimicrobial Masterbatches

- PRESS RELEASE: Antimicrobial compounds from RTP Company prolong product life