Underwriters Laboratories (UL) is an independent organization that provides product safety testing and certification. Their UL94 testing procedures and rating system for thermoplastics flammability are the generally accepted standard throughout most of the world.

Underwriters Laboratories (UL) is an independent organization that provides product safety testing and certification. Their UL94 testing procedures and rating system for thermoplastics flammability are the generally accepted standard throughout most of the world.

Different UL94 ratings are given based on variations of the test method and results:

- Horizontal Burn (HB Rating)

A specimen less than 3 mm thick is tested in a horizontal orientation. It must burn at a rate of less than 76 mm/min.

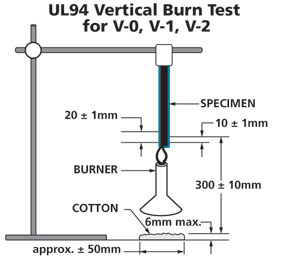

- Vertical Burn (V-0 to V-2 Rating)

Specimen thickness is a element of this classification which is conducted in a vertical orientation. Burning must self extinguish within 10-30 seconds. The effect of dripped particles can also be monitored.

Material test results must be certified by UL in order to obtain a “yellow card” or Recognized Component status and bear their “UR” mark. Use of Recognized Component materials can be advantageous for obtaining a UL Listing for completed devices.

RTP Company has over 450 plastic compounds already Recognized by UL with a variety of flammability ratings. RTP Company also participates in UL’s Client Test Data Program which allows testing conducted by RTP Company to be accepted by UL, this procedure can expedite UL certification of new materials.

Underwriters Laboratories (UL) is an independent organization that provides product safety testing and certification. Their UL94 testing procedures and rating system for thermoplastics flammability are the generally accepted standard throughout most of the world.

Underwriters Laboratories (UL) is an independent organization that provides product safety testing and certification. Their UL94 testing procedures and rating system for thermoplastics flammability are the generally accepted standard throughout most of the world.