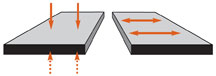

Additive Orientation

Thermal conductivity of thermoplastic compounds can be orientation dependent when high aspect ratio additives (fibers, flakes, etc.) are used because they tend to align with polymer flow during molding. This orientation can result in non-isotropic thermal conductivity where values in-plane tend to be higher than through-plane.

While metals are often chosen for their high thermal conductivity, many applications do not require this high level of thermal transfer. In fact, air movement (or convection) more often determines how effectively a system dissipates heat.

For many designs, heat sinks made of thermally conductive compounds and processed via injection molding offer greater design flexibility. This allows designers to maximize convection delivering better thermal performance while minimizing manufacturing costs.

Typically, thermally conductive compounds provide a 50% weight reduction over comparable aluminum heat sinks, especially significant in energy conscious transportation uses. Selecting the proper base resin also provides chemical resistance, eliminating corrosion that can lead to failure of metal heat sinks.

RTP Company compounds thermally conductive additives into a wide variety of plastic resins to produce compounds optimized for thermal management in a wide range of operating temperatures and environments.

Additional Benefits

- Achieve thermal conductivity up to 35 W/(m.K)

- Customizable thermal performance with variety of additives

- Can be electrically insulative or conductive

- Molded in color eliminates costly secondary operations

Typical Applications

- LED luminaires

- Consumer electronic devices

- Aerospace and automotive cooling systems

- Motor and battery housings

- Temperature sensors

- Heat exchangers

Comparative Properties for Common Compounds*

| Product | Resin | Color | Specific Gravity | Through Plane W/(m.K) |

In-Plane W/(m.K) |

Volume Resistivity ohm-cm |

Dielectric Strength kV/mm |

Flammability UL94 |

|---|---|---|---|---|---|---|---|---|

| RTP 200 TCC-C-20 FR | PA 6/6 | Black | 1.68 | 1.3 | 2.8 | 103 | — | V-0 |

| RTP 200 TC-C-21 F | PA 6/6 | Black | 1.54 | 1.3 | 4.0 | 103 | — | V-0 |

| RTP 200 TC-C-25 | PA 6/6 | Black | 1.68 | 1.4 | 4.1 | 103 | — | — |

| RTP TC-C-29 FR | PA 6/6 | Black | 1.69 | 1.5 | 7.1 | 103 | — | V-0 |

| RTP TC-C-30 FR | PA 6/6 | Black | 1.65 | 2.3 | 14.0 | 103 | — | V-0 |

| RTP 200 TC-C-40 FR | PA 6/6 | Black | 1.82 | 3.0 | 19.2 | 103 | — | V-0 |

| RTP 200 TC-C-55 | PA 6/6 | Black | 1.59 | 4.6 | 25.7 | 103 | — | — |

| RTP 200 TC-C-70 | PA 6/6 | Black | 1.71 | 6.3 | 32.0 | 103 | — | — |

| RTP 300 TC-C-20 | PC | Black | 1.5 | 1.4 | 4.5 | 103 | — | — |

| RTP 1300 TC-C-30 FR | PPS | Black | 1.7 | 2.2 | 8.0 | 103 | — | V-0 |

| RTP 200 TC-I-15 FR | PA 6/6 | White | 1.64 | 0.7 | 1.2 | 1013 | 10 | — |

| RTP 200 TC-I-20 FR | PA 6/6 | White | 1.80 | 1.0 | 1.5 | 1013 | 11 | V-0 |

| RTP 200 TC-I-25 FR | PA 6/6 | White | 1.86 | 1.5 | 5.0 | 1012 | 15 | V-0 |

| RTP 200 A TC-I-10 | PA 6 | H.R. White | 1.51 | 0.5 | 1.1 | 1011 | 15 | — |

| RTP 300 TC-I-15 | PC | White | 2.40 | 0.75 | 1.0 | 1013 | 5 | — |

| RTP 1300 TC-I-20 FR | PPS | Tan | 2.9 | 1.0 | 1.0 | 1013 | 3 | V-0 |

* Custom compounds can be formulated to meet specific application requirements.