Shielding provides “immunity” for sensitive components from incoming electromagnetic interference (EMI) and/or prevents excessive emissions of EMI to other susceptible equipment. The primary methods for preventing emission or reception of EMI are proper circuit design/grounding and selection/placement of components (including specially designed filters).

When such preventive methods fail to meet agency standards, fail to achieve proper operation of the device, or are not economical, shielding with an EMI shielding compound is an excellent alternative.

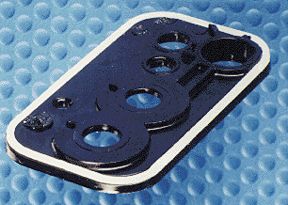

Placing a Faraday Cage around an electrical device is the fundamental principle underlying the housing technique for shielding against EMI. Faraday Cages can be constructed using metal, metallized thermoplastic, or conductive thermoplastic—a compound material that is normally transparent to EMI but has been made opaque by the use of conductive fillers. Conductive thermoplastic compounds offer superior design and manufacturing freedom and are ready for use right out of the mold.

Fibrous additives with a high aspect ratio create a conductive network within a normally insulative plastic resin. These additives can be classified into two groups:

- Metallic Substances

Stainless steel fibers, copper fibers, metal flakes/ powders/ particulates

- Metal Coated Substances

Nickel-coated graphite (NCG Fiber), metal coated substrates (non-fiber) such as nickel-graphite powder, nickel-mica, silver-glass beads

For more information about a custom conductive thermoplastic compound to help control EMI/RFI in your part or component, download our brochure or contact your local RTP Company representative today!