For more than 35 years, our engineers have been providing precise thermoplastic solutions for the automotive industry, ranging from high volume engineered materials to high tech specialty compounds. We support the industry’s commitment to sustainability by formulating thermoplastic compounds that make good sense for electric and autonomous vehicles, as well as their charging stations.

Because electric and autonomous vehicles have different requirements than internal combustion engine vehicles, the types of materials used can be very different than those that have been used historically… so we have a variety of options! Our materials are specially formulated to enhance and improve parts that are used in electric vehicles, autonomous vehicles, and charging stations, with benefits such as:

Strength

Performance

Lighter weight

Flame retardancy

Reduced VOCs

Better efficiency

Cost reduction

Applications

Click on any of the hot spots shown above to learn more about the technologies we offer for your applications. If you have any questions or would like additional information, please contact your local RTP Company representative or call us at (507) 454-6900.

RTP Company Technologies

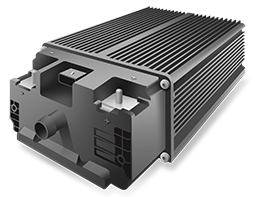

Our Electromagnetic Interference (EMI) Shielding Compounds offer reliability and value in a wide range of applications where electromagnetic compatibility is required. Shielding provides protection for sensitive components from incoming EMI and/or prevents excessive emissions of EMI to other susceptible equipment.

Typically, EMI shielding compounds utilize stainless steel fiber or nickel-coated carbon fiber in a thermoplastic matrix to provide the necessary shielding. These compounds can also incorporate flame retardant additives, wear additives, reinforcements, and colorants in a single custom material solution to meet the requirements of your application.

Housings for radar boxes, GPS module enclosures, sensors, and cameras require EMI shielding to prevent signals from being mixed or interrupted. EMI Compounds can provide this protection and help to ensure the proper function of these sensitive components.

Description

Electrically conductive or EMI absorbing PP, PA, PBT,PC/ABS

Key Characteristics

Consistent EMI shielding effectiveness up to 90+ dB

Benefits

Integrated, molded-in shielding properties

Metal-to-plastic weight savings

Cost reduction

Typical Applications

Motors

Sensor and Camera housings

Control modules

Internal charging station parts requiring electrical current management

Property Comparison: EMI Shielding Compounds Shielding Effectiveness (SE) @ 2mm Thickness

* EMI Test Method: ASTM D4935

| Technology A* | Technology B* |

|---|---|

| High SE | High SE |

| Ductile | High Modulus |

| Unreinforced | Fiber Reinforced |

| Technology C* | Technology D* |

|---|---|

| Moderate SE | Moderate SE |

| Ductile | High Modulus |

| Unreinforced | Fiber Reinforced |

Technologies A-D are available in a wide variety of base polymers, such as PP, PBT, PA66, PC, ABS, and more.

Although flammability is not often a concern with conventional gas powered vehicles, electrical and autonomous vehicles do require a fresh approach to passenger safety. Most thermoplastics utilized in the automotive industry today are inherently flammable, and therefore require an additive package to meet industry flame standards such as UL94 V-0; in addition, they must function well in the end application.

Batteries and their components benefit from Flame Retardant Compounds to help meet safety regulations and improve passenger safety.

Description

PP, PA, PBT

Key Characteristics

HB, V1, V2, V0, 5VB, and 5VA

Benefits

Risk mitigation

Colorable (safety orange, for example)

Typical Applications

LI Ion batteries

High voltage connectors

Parts with rating requirements

Battery Components: Housings, Frames, Plates, Trays

| Formula | Description | UL 94 Flammability | Tensile Strength (MPa) | Flexural Modulus (GPa) | Charpy Notched Impact (kJ/m2) | HDT @ 1.82 MPa (°C) | Density | Filler Content |

|---|---|---|---|---|---|---|---|---|

| RTP 199 X 135008 A | PP – Glass Fiber – FR | V-0/5VA | 80 | 7.2 | 8.2 | 145 | 1.50 | 30 |

| RTP 199 X 151875 A | PP – Unfilled – FR | V-0 | 25 | 1.1 | 5.8 | 52 | 1.00 | N/A |

| RTP 199 X 156119 B | PP – Mineral – FR | V-0/5VA | 27 | 2.9 | 3 | 70 | 1.35 | 20 |

| RTP 199 X 163680 | Glass Fiber Reinforced FR V-0 PP | V-0 @ 1.5mm | 60 | 6.5 | 10.0 | 135 | 1.32 | 30% GF |

| RTP 299 X 164401 A | Glass Fiber Reinforced FR V-0 Nylon 6,6 | V-0 @ 0.8mm | 135 | 8.8 | 7.0 | 240 | 1.37 | 25% GF |

| RTP 299 A X 163684 | Glass Fiber Reinforced FR V-0 Nylon 6 | V-0 @ 0.8mm | 130 | 10.0 | 10.0 | 216 | 1.44 | 30% GF |

| RTP 299 K X 138337 C | PARA – Glass Fiber – FR | V-0/5VA | 193 | 15.9 | 11.5 | 210 | 1.57 | 40 |

| RTP 299 K X 138337 E | Glass Fiber Reinforced FR V-0 PARA | V-0 @ 0.5mm | 214 | 20.7 | 20.0 | 210 | 1.69 | 50% GF |

| RTP 399 X 143586 | PC – Transparent – Unfilled – FR | V-0/5VA | 69 | 2.7 | 12.2 | 125 | 1.24 | N/A |

| RTP 2099 X 150722 A | PA Alloy – Glass Fiber – FR | V-0/5VA | 131 | 9.3 | 17 | 188 | 1.56 | 30 |

| RTP 4099 X 163681 | Glass Fiber Reinforced FR V-0 PPA | V-0 @ 0.8mm | 160 | 11.0 | 7.0 | 280 | 1.45 | 30% GF |

Electrical Components: High Voltage Connectors, Terminal Covers, Telecommunication Housings

| Formula | Description | UL 94 Flammability | Tensile Strength (MPa) | Flexural Modulus (GPa) | Charpy Notched Impact (kJ/m2) | HDT @ 1.82 MPa (°C) | Density | Filler Content |

|---|---|---|---|---|---|---|---|---|

| RTP 199 X 134952 B | PP – Mineral Filled – FR | V-0/5VA | 22 | 2.2 | 4.5 | 70 | 1.31 | 15 |

| RTP 199 X 137777 D | PP – Unfilled – FR | V-0 | 31 | 1.4 | 2.3 | 55 | 1.02 | N/A |

| RTP 1099 X 149490 | PBT – Glass Fiber – FR – Low Warp | V-0/5VA | 134 | 9.5 | 8.8 | 204 | 1.63 | 30 |

| RTP 1099 X 156121 A | PBT – Glass Fiber – FR | V-0/5VA | 136 | 9.7 | 8 | 210 | 1.63 | 30 |

Outdoor Components: Connectors, In Cable Circuit Breakers/Control Boxes, Charging Station Housings

| Formula | Description | UL 94 Flammability | Tensile Strength (MPa) | Flexural Modulus (GPa) | Charpy Notched Impact (kJ/m2) | HDT @ 1.82 MPa (°C) | Density | Filler Content |

|---|---|---|---|---|---|---|---|---|

| RTP 199 X 138253 A | PP- Unfilled UV – FR | V-0 | 24 | 1.2 | 47 | 52 | 1.04 | N/A |

| RTP 2099 X 143976 D | PC/PBT – Unfilled – UV – FR | V-0/5VA | 48 | 2.1 | 48 | 88 | 1.29 | N/A |

Underhood Components: Engine Covers, Electrical Components

| Formula | Description | UL 94 Flammability | Tensile Strength (MPa) | Flexural Modulus (GPa) | Charpy Notched Impact (kJ/m2) | HDT @ 1.82 MPa (°C) | Density | Filler Content |

|---|---|---|---|---|---|---|---|---|

| RTP 299 X 150941 A | PA 66 – Glass Fiber – FR | V-0 | 125 | 7.0 | 6.5 | 235 | 1.56 | 15 |

| RTP 299 X 156120 A | PA 66 – Glass Fiber – FR | V-0 | 150 | 9.5 | 6.2 | 245 | 1.65 | 25 |

| RTP 299 A X 157486 A | PA 6 – Glass Fiber – FR | V-0 | 125 | 7.0 | 15 | 200 | 1.54 | 15 |

Our Structural Compounds provide solutions in applications requiring excellent mechanical and/or thermal performance.

Short Glass Fiber (SGF) Compounds – chopped glass fiber provides strength and stiffness to our SGF compounds, which provide good, general purpose reinforcement.

Very Long Fiber (VLF) Compounds – in addition to the improvement in strength and stiffness versus SGF Compounds, VLF Compounds provide improved impact strength and are commonly used for metal replacement.

Carbon Fiber (CF) Compounds – our CF Compounds provide tremendous stiffness without adding significant weight to a vehicle. These high end materials, which are commonly used in aerospace, are finding broader use for lightweighting in electric and autonomous vehicles.

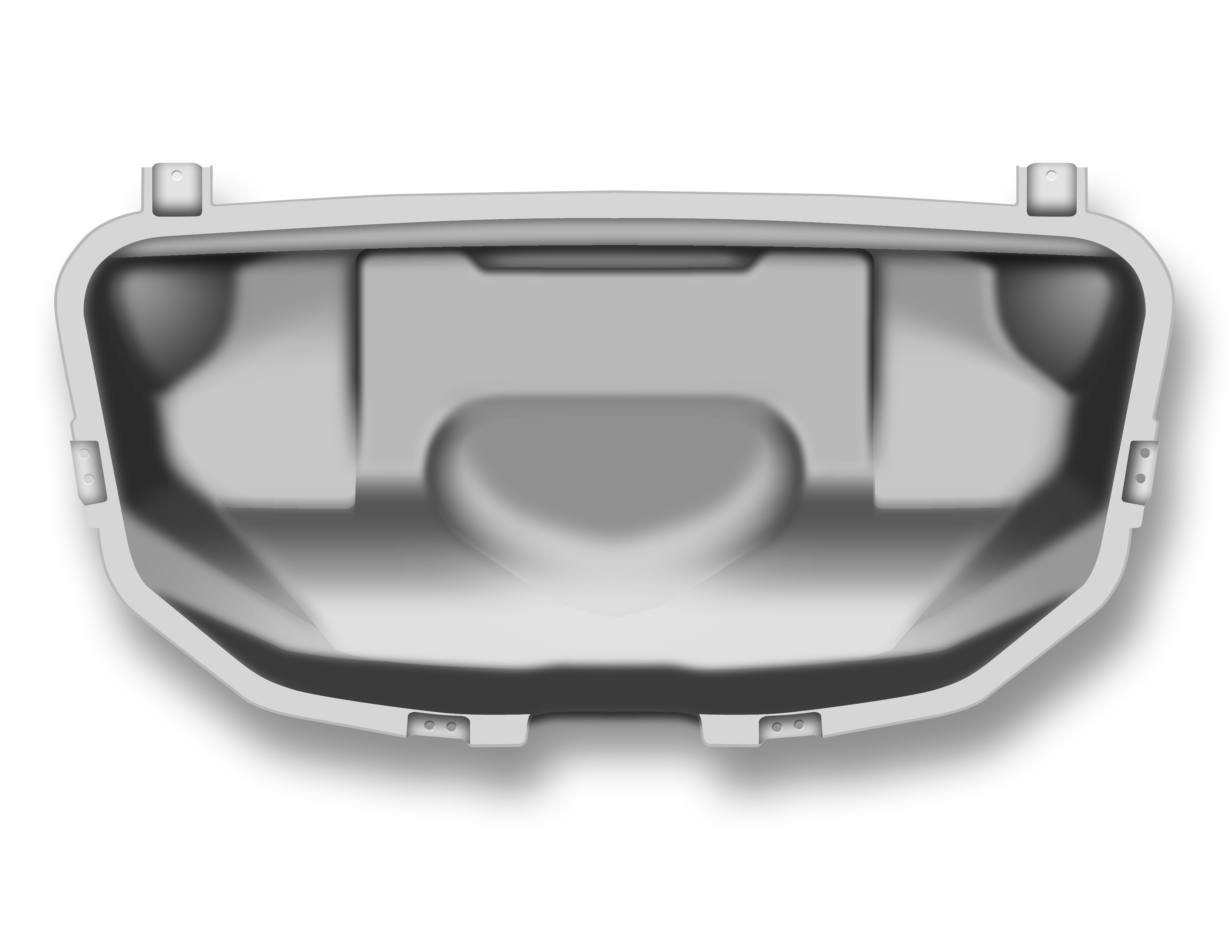

The “frunk”, or storage space under the front hood of an electric or autonomous vehicle, can be made from VLF Compounds for excellent durability and impact.

Description

Long Glass/Short Glass Fiber PP, PA, PBT; Carbon Fiber (CF) Compounds; ASA Alloys

Key Characteristics

Provide outstanding impact resistance, creep resistance, and aesthetic value

Benefits

Dimensional stability

Durability

Excellent for metal replacement

Reduce part weight

Colorable

Typical Applications

Battery plates

LI Ion battery housing cover

Frunk

Camera brackets/Sensor housings

Instrument panels

Interior trim

Outdoor housings and base units for charging stations

| RTP Company Material Options | |||||||

|---|---|---|---|---|---|---|---|

| RTP 299 A X 143325 A | RTP 299 A X 149343 A | RTP 199 X 154150 B | RTP 199 X 70815 |

RTP 199 X 70836 A | |||

| Property | Method | Unit | PA6 30% SGF | PA6 30% SGF Low Density | PP 20% CF | PP 30% VLF | PP 40% VLF |

| Density | ISO 1183 | g/cm3 | 1.35 | 1.22 | 1.00 | 1.13 | 1.20 |

| Tensile Strength | ISO 527 | MPa | 180 (113) | 167 (115) | 105 | 110 | 130 |

| Flexural Modulus | ISO 178 | MPa | 9500 | — | 9233 | 6500 | 8500 |

| Charpy Impact, Notched | ISO 179/1eA | kJ/m2 | 13 (15) | 10 (12) | 4.0 | 21 | 25 |

*All values Dry As Molded except those in parentheses, conditioned 23 °C, 50% RH to equilibrium.

For applications that require aesthetics, UV protection, and weatherability, we formulate ASA Alloys that provide high gloss, colorability, and UV performance. In addition, these alloys provide higher chemical resistance and thermal stability versus standard ABS, making them an excellent choice for thermoplastic housings on charging stations.

UV Resististance

| Property | ABS | PC/ABS | PP | PA | ASA |

|---|---|---|---|---|---|

| UV Resistance | POOR | POOR | BETTER | BETTER | BEST |

Our high temperature compounds are formulated to withstand high heat environments, making them an excellent choice for electric motors, battery systems, and mating connectors. Made from resins that inherently offer better mechanical performance and both wear and chemical resistance, we can also tailor these products to meet specific application requirements. By selecting from a broad range of polymer and additive combinations, we can provide the precise color, mechanical function, wear resistance, dimensional stability, conductivity, and regulatory requirements of your application in a single, cost optimized solution.

High Temperature Mineral Filled Compounds provide improvements in dimensional stability and stiffness in high temperature environments over unmodified resin.

Description

PSUL, PES, PPSU, PEI, PEEK, PPA, PPS, TPI, HTN

Key Characteristics

Withstand high heat environments and higher continuous use temperatures

Benefits

Consolidate parts

Reduce part weight

Inherent wear and chemical resistance

Provide design freedom

Typical Applications

Motors

Battery systems

Mating connectors

Color can be used in many ways, including to draw attention, communicate instructions, enhance safety features, build brand awareness, create special effects, and more. Choose from our standard color palette or request a custom color match! Our color compounds are available in Precolor, Masterbatch, or Cube Blend, and can be enhanced with functional additives such as UV protection packages to prevent fade and deterioration for applications such as exterior housings or charging stations.

Our Color Engineering Team uses high end spectrophotometers and their extensive knowledge to ensure your thermoplastic custom color is precise and can withstand harsh outdoor elements.

Description

Precolor, Masterbatch, Cube Blend

Key Characteristics

100% color matched UV stable

Benefits

Harmony with interior trim color

Special effects like metallics

Typical Applications

Interior hard trim

UV protected color for charging stations

From off-the-shelf resins to complex custom compounds, our TPEs provide unique benefits for electric and autonomous vehicles, including improved ergonomics, noise reduction, and superior sealing ability. Available in durometers ranging from 10 shore A to 65 shore D, they are commonly used in automotive parts such as seals, gaskets, air deflectors, handles, and grips. Our Nylabond™ and Polabond® materials are bondable to various substrates including Nylon, ABS, PC, PC/ABS and other engineering resins, while our high temperature TPV technology bonds well to nylon substrates for applications used in extreme environments.

Our NylabondTM nylon bondable TPVs can be overmolded to a rigid substrate to improve part integrity, eliminate the need for adhesives, and enhance grip performance for parts like gear knobs.

Description

Nylabond™ Nylon Bondable TPV

Key Characteristics

55A to 85A Durometer

Benefits

Sealing

Ergonomics

Flexibility

Typical Applications

Seals

Air deflector

Miscellaneous

Our Wear and Friction Resistant compounds solve a number of issues, including noise, abrasion, friction, and scratching/marring. Noise is particularly important in the case of electric and autonomous vehicles, since the expectation is a quiet cabin. Molded parts made from our wear and friction resistant compounds can be internally lubricated and provide noise reduction between mated or sliding parts. In addition, they provide protection from scratching and marring of surfaces, as well as excellent oxidation and corrosion resistance for handles, latches, gears, bushings, and more.

Our wear and friction resistant compounds can reduce noise, provide scratch protection, and extend the service life of parts like vehicle door handles.

Description

Internally lubricated compounds; PTFE, Graphite, Moly, Silicone

Key Characteristics

Reduce wear and friction

Benefits

Eliminate grease and squeaks

Extend product life

Typical Applications

Latches

Gears and bushings

Seals and gaskets

Several divisions of RTP Company provide special materials designed with the automotive market in mind. For example, we can provide reclaimed fiber materials, ideal for cargo/frunk liners and mats, or diffused lighting compounds for dashboard controls.

Only RTP Company offers the widest selection of material solutions for every aspect of electric and autonomous vehicles!

Description

Sheet, film, and fiber materials

Key Characteristics

Varies by material

Benefits

One source for a wide range of EV materials

Typical Applications

Trunk lining

Floor mats

Lighted control panels